REDUCING OUR CARBON EMISSIONS TO ZERO!

What’s the rush?

The fight against climate change is a fight against the clock. While a temperature increase of just 1°C might feel negligible at home, a similar increase in global surface temperature can have devastating consequences. As we can already see from increased droughts, record heatwaves and violent storms. In many regions, warming has already surpassed 1.5°C, significantly above pre-industrial levels. In short: we don’t have the luxury of time.

According to the Intergovernmental Panel on Climate Change (IPCC) and just about every climate scientist on the planet, the main driver of climate change is an excess of greenhouse gasses due to human activity. If we want to stand a chance at preventing a climate catastrophe, we must drastically reduce our carbon emissions.

We have to act fast, act together and act NOW!

A quick refresher on scopes 1, 2 and 3

Greenhouse gas emissions are categorised into three groups or Scopes by the most widely-used international accounting tool, the Greenhouse Gas (GHG) Protocol. Carbon emissions are responsible for a massive 81% of all GHG emissions and businesses are accountable for most of it. Of course, if you want to measure any progress companies make in reducing their emissions, you need a standardised tool. That’s where the Scopes come in.

So what are these 3 scopes?

• Scope 1 emissions are ‘direct’ emissions: those that a company causes - such as the manufacturing of our products.

• Scope 2 emissions are ‘indirect’ emissions: from electricity consumption

• Scope 3 emissions are all other indirect emissions from the whole value chain. They cover the emissions related to sourcing of raw material, use and end of life of the products, upstream and downstream logistics etc.

Smart solutions and clean energy

Making high-quality automotive glazing requires energy. There’s little we can change about that. But what we can do is optimise processes, use most advanced technologies, use clean energy from renewable resources to bring our carbon emissions down to where we want them to be. ZERO.

Reducing our scope 1 and 2 emission to zero

When it comes to reducing our carbon emissions, our goal at Sekurit Service is clear:

→ reduce CO2 emissions by 100% on scopes 1 and 2 (by 2030 vs 2019), while reaching several intermediate goals along the way.

Switching our energy mix to renewable sources

Most of our carbon impacts are concentrated at our plants both located in Europe – Tartu (Estonia) & Zary (Poland). In the past years, we have driven efforts to reduce first the energy consumption and then by switching to renewable energy.

For instance:

- 100% of the electricity used in our Estonian factory is now sourced from green energy with Biomass.

- Zary AGR is supplied by 100% green energy (covered by guarantees of origin).

→ Thanks to our efforts, we have already reduced our CO2 emissions

(scopes 1 & 2) from our plants by 70% compared to 2019.

We don’t limit our actions to our plants, we also implement initiatives in our logistics centres notably by reducing energy consumption through LED retrofit, presence detection and the optimisation of natural light but also having electrical forklifts and finally encourage eco-gesture with our BIG Little Moves internal campaign etc.

Exemplary on our own operations

We’ve also installed a wind turbine at our central warehouse in Bastogne, which provides roughly 56% of the total electricity needed there. The remaining energy is covered by a low-carbon energy contract for the facility.

Another example is in Nimes, our warehouse is equipped with 4800 solar panels, covering roughly 4500 m2!

We want to be exemplary on our own operations (scopes 1 & 2) and as a leader we want to engage the whole value chain by also committing on our scope 3.

In the next Sekurit Service Made in Europe newsletter, we’ll tell you more about the actions we’re taking to reduce our Scope 3 emissions as well.

→ By 2030, these will be reduced by at least 30%.

More sustainable products, with the lowest carbon footprint

All these actions are concrete proof of our commitment towards carbon neutrality and will reduce the carbon footprint of our products. Thus, our objective is to provide more sustainable products for our customers with the lowest carbon footprint.

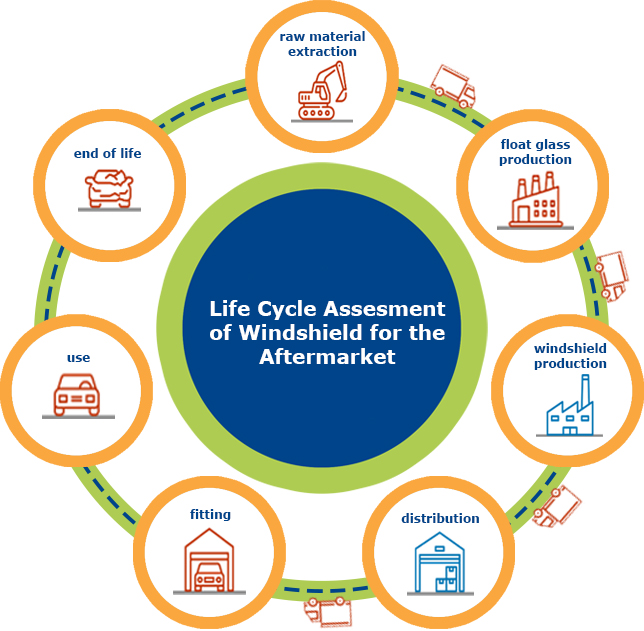

To do so, Life Cycle Assessment (LCA) tool is used as it allows us to identify and quantify environmental impacts in order to reduce them (see Newsletter 1 for more information about LCA).

We are fully aware of the Life Cycle Assessment of a windshield for the aftermarket:

→ Did you know that 18% of the footprint for the entire life cycle of a Sekurit Service windscreen comes from logistics and packaging?

→ Being Made in Europe – local and close by is a huge driver to reduce the carbon footprint as it accounts for nearly one fifth of the total emissions of the product.

Stay tuned on our Made in Europe story, there’s more to follow next month!