GOING IN CIRCLES. IN A GOOD WAY.

Let’s talk about circular economy

This year, on August 2nd to be exact, the NGO Global Footprint Network calculated that we will reach “Earth Overshoot Day 2023”. The point at which humanity’s demand for ecological resources and services exceeded what the Earth was able te regenerate that year. It’s clear the traditional linear model of ‘take-make-use-dispose’ is no longer viable. What the Earth needs is a circular economy.

Maximising the reintroduction of end-of-life windscreens

While the idea of a circular economy itself isn’t new, the concept of keeping materials, products and services in circulation for as long as possible has become increasingly relevant in the fight against climate change and the preservation of a habitable planet. According to the UN, natural resource extraction and processing contribute to about half of all global greenhouse gas emissions. Which is exactly why we aim to reintroduce the maximum amount of end-of-life windshields into our production lines at Saint-Gobain, either in flat glass production, when possible, or other glazing products such as insulation.

Turning a waste into a resource

Circular Economy has to be presented to our customers as an added value that we are capable to offer them. Basically, after performing their job they have this heavy, bulky and unusable waste. However this waste can once again become a resource. It can even get back to the windshield production; allowing raw material, energy and carbon emission savings from the production stage.

Due to our unique positioning across the whole value chain, we know perfectly how to really recycle glass and not downcycling, meaning recycling it in a lower quality or functionality than originally. Thus our goal at Sekurit Service is to offer this service to our customers. A turnkey solution to manage their waste in a proper and efficient and way that reduces environmental impact.

Reversing logistics, reintroducing back to production

We already have some examples across Europe when we are experimenting this flow back to our production line. First illustration, in the West of Germany, we have a pilot project where we collect windshield waste from our customers. Thanks to reverse logistics, we massify the flows and send them to an agreed partner who depollutes and treats the waste to obtain a good quality cullet that our flat glass plant reintroduces into its production.

Initiatives of this kind are multiplying across Europe, notably in Estonia, Poland, France and Spain and our objective is to be able to offer this take back service in all our countries by 2030.

A real win-win service! This offer of properly recycling this 100% recyclable material is one of the most efficient ways to reduce the carbon footprint of a windshield production and preserve raw material consumption.

Did you know?

Reintroducing one ton of broken glass (cullet) into a flat glass furnace saves 1,2 tons of primary raw material, out of which 850 kilograms is sand and 300kg of CO2 emissions.

Closing the loop – with other waste too

Glazing products are not the only waste that we can take care of from our customers. To reduce windshield damage and increase quality, in some countries, we now wrap windshields into plastic films made with recycled granules. This protective coating is very useful for transporation and handling of the product, but can rapidly become a waste that needs to be properly treated. As plastic can also be recycled, we are now collecting plastic film from our customers during our milk round. We then compress them in our warehouse, before finally sending them to our main supplier in order to be reinjected into their production lines. Once again a concrete example of closing the loop where a waste can be a resource.

Small steps in a long journey, beginning with key partnerships

It is the beginning of our journey in terms of circular economy and we are truly committed to bringing solutions for our customers, while reducing impact of our production, using our local logistics network.

At Sekurit Service we value the necessity to partner with key actors across the whole business value chain. Both local and national – from recycling companies, to logistics networks and service providers to suppliers.

Being a Sekurit Service partner means complying with environmental regulations, preferably going above and beyond minimum requirements. We choose providers and subcontractors that share our values, respect human rights and limit their impact on the environment.

For more information, please contact your local representative or get in touch via contact us

--> Follow our Made in Europe story (click for more info):

#1 - Sekurit Service commitment to sustainability

#2 - Reducing our direct & indirect carbon emissions to zero (more about Scopes 1 & 2)

#3 - Reducing our emissions along the value chain (more about Scope 3)

#4 - The fight against the climate change

--> Read more news about Sustainability and CSR (click for more info):

Sekurit Service Sustainability Roadmap

Saint-Gobain Automotive Glazing Replacement receives GOLD EcoVadis Rating

Gold Award for Saint-Gobain Glass Estonia SE Recognition by the Responsible Business Index (VEF)

Al deze acties zijn een concreet bewijs van ons streven naar koolstofneutraliteit en zullen de ecologische voetafdruk van onze producten verkleinen. Het is dus ons doel om onze klanten duurzamere producten te bieden met de laagste ecologische voetafdruk.

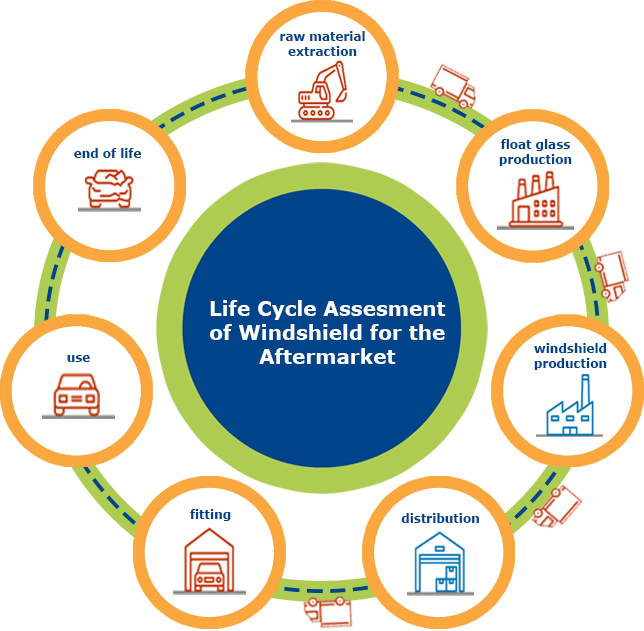

Hiervoor wordt gebruik gemaakt van de levenscyclusanalyse (LCA), waarmee we de milieueffecten kunnen identificeren en kwantificeren om ze te verminderen.

We zijn volledig op de hoogte van de levenscyclusanalyse van een voorruit voor de aftermarket:

→ Wist u dat 18% van de voetafdruk voor de gehele levenscyclus van een Sekurit Service voorruit afkomstig is van logistiek en verpakking?

→ Made in Europe – lokaal en dichtbij is een enorme drijfveer om de ecologische voetafdruk te verkleinen, aangezien het verantwoordelijk is voor bijna een vijfde van de totale uitstoot van het product.